At Labzenix.com, we specialize in providing advanced testing instruments designed to meet the quality control demands of modern industries. One of our flagship products, the Bursting Strength Tester, plays a crucial role in measuring the strength and durability of materials like paper, cardboard, textiles, and packaging films.

What Does a Bursting Strength Tester Do?

A Bursting Strength Tester evaluates how much pressure a material can withstand before it bursts. The device applies hydraulic pressure to a sample through a rubber diaphragm. As the pressure builds, the material eventually ruptures, and the tester records the pressure value at the moment of burst. This measurement helps determine the material’s ability to handle stress during packaging, shipping, and everyday use.

Why Bursting Strength Testing Matters

Whether you're manufacturing boxes, printing paper, or producing fabric, knowing how strong your material is under pressure is essential. A weak material can lead to product damage, returns, and dissatisfied customers.

Key advantages of performing bursting strength tests:

Product quality assurance: Identify weak spots in raw materials before production.

Standards compliance: Meet global quality standards like ASTM, ISO, and TAPPI.

Reduced waste and costs: Minimize product failures and packaging issues.

Customer satisfaction: Deliver consistently strong, reliable materials to your clients.

Top Features of Labzenix Bursting Strength Testers

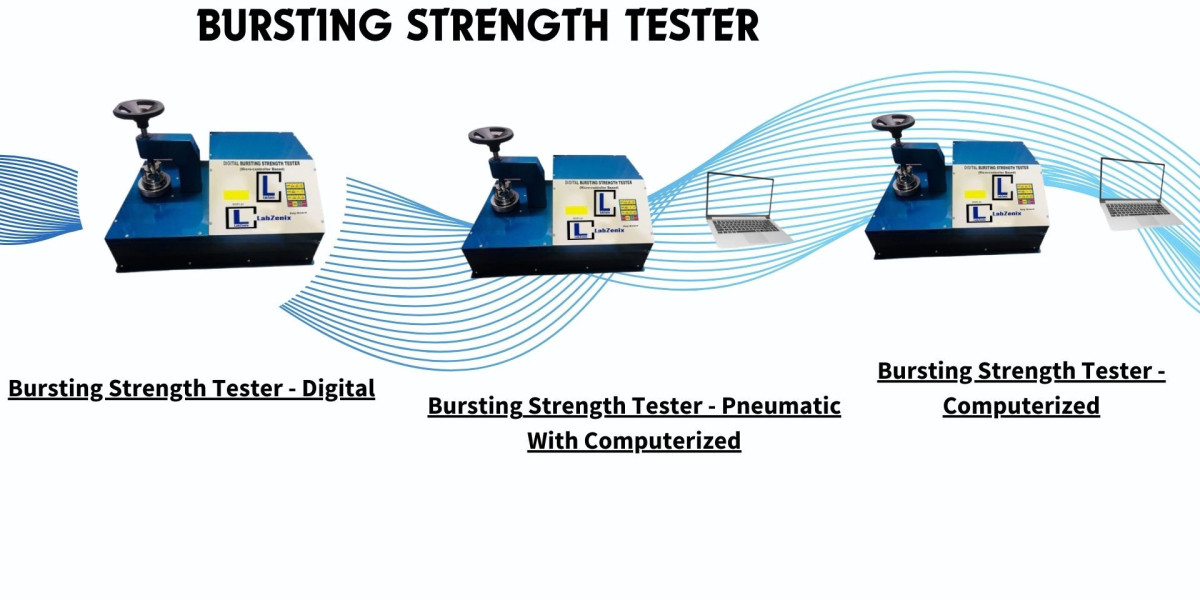

Our testers are engineered for precision, ease of use, and durability. Whether you're in a high-volume factory or a small QC lab, Labzenix offers the right configuration for your needs.

Our testers come equipped with:

Digital display for accurate, real-time pressure readings

Automatic burst detection to improve testing speed and consistency

Strong clamping mechanism to secure samples in place during testing

Sturdy construction for long-term use in industrial environments

We also offer customizable models and support for different international testing standards.

Industries That Use Bursting Strength Testers

Bursting strength testing is crucial across multiple sectors:

Paper and packaging – Evaluate the strength of paper, cartons, and corrugated boxes

Textiles – Test fabrics for garments, upholstery, and technical applications

Leather and synthetics – Check material strength for bags, shoes, and accessories

Industrial materials – Ensure reliability in automotive, aerospace, and construction components

No matter the application, this test ensures that your material can handle real-world conditions.

Complies with Global Testing Standards

Our equipment supports a wide range of industry standards, including:

ASTM D3786 – Bursting strength of textile fabrics

ISO 2758 & ISO 2759 – Paper and board bursting strength

TAPPI T403 – Paper bursting strength methods

Compliance with these standards ensures your products are suitable for international markets and regulatory bodies.

Why Labzenix?

At Labzenix, we’re more than a supplier—we’re your testing partner. Our mission is to deliver reliable, high-performance equipment backed by expert support and training. We understand the demands of modern manufacturing and quality control, and we design our products to meet them head-on.

Whether you're a small lab or a large-scale manufacturer, Labzenix has the equipment and support you need to keep quality at the forefront of your operations.