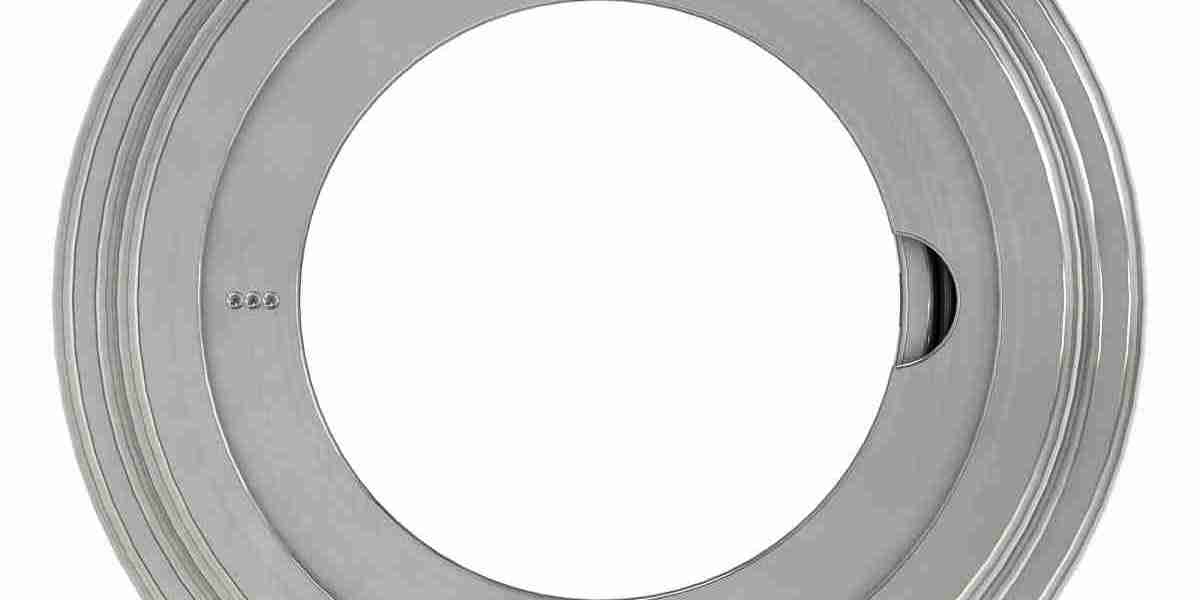

When machinery starts showing unusual vibrations, noise, or overheating, one of the key suspects is the bearing. The ah229175 bearing, designed for durability, is not immune to issues. If ignored, minor bearing faults can escalate into severe damage, costly downtime, or even equipment failure.

This article explores common problems with the AH229175 bearing, their root causes, and practical solutions that extend performance life.

Common Problems with AH229175 Bearing

Even high-grade bearings like the AH229175 face wear and tear under heavy loads and harsh environments. Typical issues include:

Excessive noise – often caused by surface wear, contamination, or lack of lubrication.

Overheating – linked to misalignment, poor lubrication, or friction buildup.

Vibration and instability – usually due to shaft imbalance, fatigue cracks, or improper installation.

Understanding these signs early can save both time and repair costs.

Causes of Bearing Failure

Failures are rarely sudden; they usually develop from preventable factors. With the AH229175, common causes include:

Lubrication failure – using the wrong grease or neglecting timely relubrication.

Contamination – dust, dirt, or metal particles entering the bearing raceways.

Improper installation – incorrect mounting techniques leading to misalignment.

Overloading – exceeding design limits shortens lifespan significantly.

Identifying the cause ensures the right corrective measures are taken.

Preventive Maintenance for AH229175

To avoid unexpected breakdowns, preventive care is essential. Key steps include:

Regular lubrication schedules with the correct grease.

Monitoring operating temperature and vibration levels.

Using protective seals to block contamination.

Following torque specifications during installation.

By applying these measures, the AH229175 can run smoothly for years.

Repair vs. Replacement: Making the Right Choice

When failure signs appear, businesses face a choice: repair or replace. In most cases, severe wear or internal cracks mean replacement is safer. Choosing a new ah229175 bearing ensures reliability, whereas short-term repairs may not solve root issues.

Replacement should always be considered if the bearing shows repeated overheating, scoring, or material deformation.

Conclusion

The AH229175 bearing is a high-performance component, but like any mechanical part, it requires proper care. Ignoring noise, vibration, or heat can result in unexpected downtime and costly repairs. By understanding common problems, their causes, and timely maintenance strategies, you can ensure long-term performance. When necessary, replacing the bearing is often the smartest investment.